The Advantages of Industrial Reverse Osmosis Systems for Water Treatment

By:Admin

Water is an essential resource for many industries, and ensuring a sustainable and reliable water supply is crucial for business operations. With this in mind, {Company Name} has developed an advanced Industrial Reverse Osmosis System that offers an effective and environmentally friendly solution for water treatment and purification.

{Company Name} is a leading provider of water treatment solutions, with a strong focus on innovation and sustainability. With over 20 years of experience in the industry, the company has become a trusted partner for businesses looking to improve their water management practices. The Industrial Reverse Osmosis System is the latest addition to their range of products, and it has already garnered attention for its efficient and cost-effective operation.

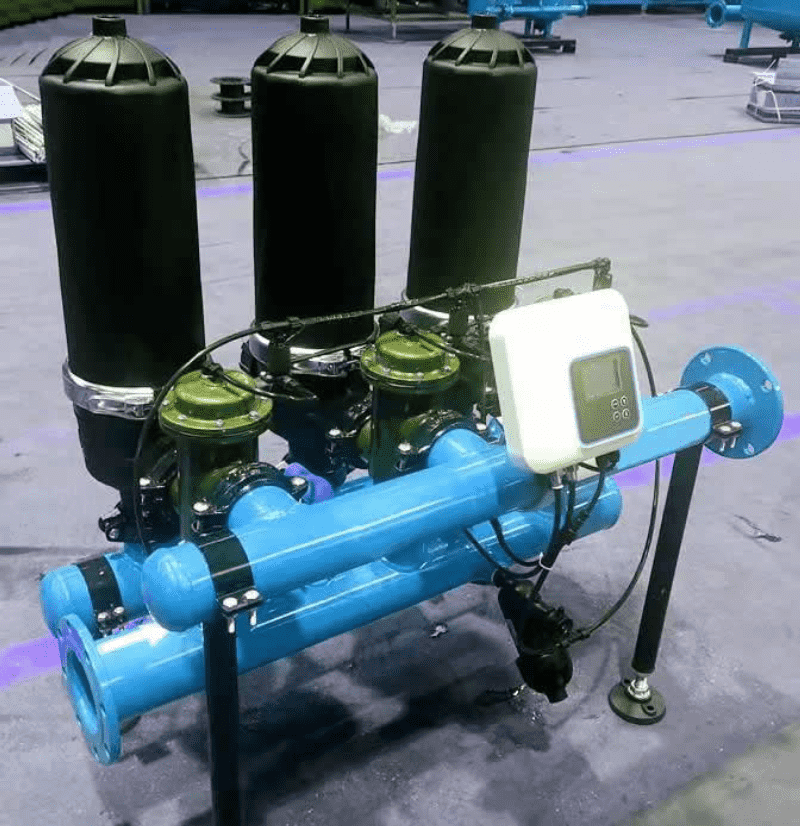

The Industrial Reverse Osmosis System is designed to tackle the water challenges faced by industrial facilities, such as manufacturing plants, power stations, and food processing facilities. With its advanced membrane technology, the system is able to remove impurities and contaminants from water, producing high-quality, clean water that meets the stringent standards set by regulatory bodies.

One of the key advantages of the Industrial Reverse Osmosis System is its ability to provide a sustainable water solution for companies. By utilizing the process of reverse osmosis, the system is able to reduce the overall water consumption of industrial processes, leading to significant cost savings and environmental benefits. This makes it an ideal choice for businesses looking to improve their water efficiency and reduce their environmental footprint.

In addition to its sustainability benefits, the Industrial Reverse Osmosis System is also highly efficient and reliable. With its automated control system and advanced monitoring capabilities, the system can operate continuously with minimal oversight, ensuring a reliable and consistent supply of clean water for industrial operations. This level of reliability is essential for businesses that rely on a steady water supply to maintain their production processes.

Furthermore, the Industrial Reverse Osmosis System is designed to be easy to install and maintain, minimizing downtime and operational disruptions for businesses. {Company Name} provides comprehensive support and maintenance services for the system, ensuring that it continues to operate at peak performance over its lifespan. This level of support gives businesses the peace of mind that their water treatment solution is being taken care of by experts in the field.

The Industrial Reverse Osmosis System has already been implemented by several businesses across a range of industries, with positive results. One company, a leading manufacturer of electronic components, reported a significant reduction in their water costs and an improvement in the quality of their water supply after installing the system. Another company, a food processing facility, was able to meet the stringent water quality standards required for their operations, thanks to the system’s advanced purification capabilities.

Looking ahead, {Company Name} is committed to further developing and improving its Industrial Reverse Osmosis System, as well as expanding its range of sustainable water treatment solutions. With a focus on innovation and customer satisfaction, the company aims to continue providing businesses with the tools and expertise they need to achieve their water management goals.

In conclusion, the Industrial Reverse Osmosis System offered by {Company Name} is a game-changer in the field of industrial water treatment. With its sustainable, efficient, and reliable operation, the system provides businesses with a cost-effective and environmentally friendly solution for their water management needs. As the demand for sustainable water solutions continues to grow, {Company Name} is well positioned to meet the needs of businesses across a range of industries, helping them improve their water efficiency and reduce their environmental impact.

Company News & Blog

High-Quality FRP Pressure Tank Vessel for Industrial Use

[Company Introduction] As a leading manufacturer and supplier of high-quality industrial equipment, our company has been at the forefront of providing innovative solutions for various applications in the oil and gas, water treatment, and chemical industries. With a strong emphasis on quality, reliability, and technological advancements, we have earned a reputation for delivering products that meet the highest industry standards.Our extensive range of products includes pressure vessels, filtration systems, and fluid handling equipment that are designed to withstand the most demanding operating conditions. With a commitment to excellence and customer satisfaction, we continuously strive to improve and expand our product offerings to meet the evolving needs of our clients.[FRP Pressure Tank Vessel]We are pleased to announce the launch of our latest product – the FRP pressure tank vessel. This new addition to our product line is designed to provide a cost-effective and reliable solution for various pressure vessel applications in the industrial sector. The use of high-quality materials and advanced manufacturing techniques ensures that our FRP pressure tank vessels offer superior performance and durability.Fiber reinforced polymer (FRP) has become increasingly popular in the manufacturing of pressure vessels due to its exceptional strength-to-weight ratio, corrosion resistance, and long-term reliability. Our FRP pressure tank vessels are engineered to deliver high-pressure performance while minimizing the risk of corrosion and leakage, making them an ideal choice for a wide range of industrial processes.Key features of our FRP pressure tank vessels include:1. Corrosion resistance: The use of FRP materials ensures that our pressure tank vessels can withstand the corrosive effects of chemicals and harsh operating environments, making them suitable for applications in the water treatment and chemical processing industries.2. Lightweight design: The lightweight nature of FRP allows for easy handling and installation, reducing overall transportation and labor costs while maintaining structural integrity and strength.3. Customizable options: Our FRP pressure tank vessels are available in a variety of sizes and configurations, allowing for custom solutions to meet specific project requirements and space constraints.4. Long service life: With proper maintenance and care, our FRP pressure tank vessels are designed to provide reliable performance and longevity, ultimately reducing lifecycle costs for our customers.In addition to offering standard FRP pressure tank vessels, we also provide custom fabrication services to cater to specialized requirements and unique project specifications. Our experienced team of engineers and technicians are committed to delivering tailored solutions that meet the highest standards of quality and performance.At our facility, we utilize advanced manufacturing processes and quality control measures to ensure that every FRP pressure tank vessel that leaves our production line meets or exceeds industry standards. Furthermore, our dedication to continuous improvement and innovation allows us to stay ahead of the curve and provide our customers with cutting-edge solutions that address their evolving industrial needs.In conclusion, our new FRP pressure tank vessel represents a significant addition to our expanding product portfolio, demonstrating our ongoing commitment to delivering reliable and cost-effective solutions for our customers' pressure vessel requirements. With its exceptional performance and longevity, our FRP pressure tank vessels are poised to set a new standard in the industry and provide our clients with a competitive advantage in their respective markets.

Top Water Treatment Equipment for UF Systems

UF Water Treatment Equipment Revolutionizing Clean Water AccessWater is essential for life, and access to clean and safe water is a basic human right. Unfortunately, millions of people around the world still lack access to clean and safe drinking water. This has led to an increase in waterborne diseases and health issues, especially in developing countries. To address this global challenge, [company name] is revolutionizing the water treatment industry with its state-of-the-art UF water treatment equipment.[Company name] has been at the forefront of water treatment solutions for over two decades. With a strong commitment to innovation and sustainability, the company has developed a wide range of water treatment products that cater to the needs of various industries and communities. From residential water purification systems to industrial-scale water treatment plants, [company name] offers comprehensive solutions to ensure access to clean and safe water for everyone.One of the key technologies that [company name] has pioneered is the Ultrafiltration (UF) membrane technology. UF is a highly effective water treatment process that removes bacteria, viruses, and other contaminants from water, making it safe for consumption. The UF membrane acts as a barrier, allowing only clean water molecules to pass through while blocking out harmful particles. This technology has proven to be a game-changer in the water treatment industry, as it provides a cost-effective and sustainable solution for clean water access.The UF water treatment equipment developed by [company name] is designed to meet the highest quality and performance standards. The equipment is easy to install, operate, and maintain, making it ideal for both residential and commercial use. Whether it's a small community water supply project or a large-scale industrial application, [company name] has the expertise and resources to deliver customized UF water treatment solutions to meet the specific needs of its clients.In addition to its cutting-edge technology, [company name] places a strong emphasis on environmental sustainability. The UF water treatment equipment is designed to minimize energy consumption and reduce waste generation, making it an eco-friendly choice for clean water solutions. Furthermore, the company is dedicated to promoting water conservation and responsible water management practices, aligning with its mission to contribute to a more sustainable and water-secure future.One of the key advantages of [company name]'s UF water treatment equipment is its ability to deliver consistent and reliable performance. The UF membrane technology ensures that the treated water meets the highest quality standards, surpassing regulatory requirements and guidelines. This makes the equipment an ideal choice for communities and industries that require a dependable and long-term water treatment solution.Apart from its technical excellence, [company name] is also known for its comprehensive customer support and service. The company works closely with its clients to understand their specific water treatment needs and provides tailored solutions to address them. From initial consultation and system design to installation and ongoing maintenance, [company name] is committed to delivering a seamless and hassle-free experience for its customers.As the global demand for clean water continues to grow, [company name] remains dedicated to driving innovation and advancing water treatment technologies. The UF water treatment equipment developed by [company name] is a testament to the company's unwavering commitment to making clean and safe water accessible to all. By harnessing the power of UF membrane technology, [company name] is transforming the way water is treated and setting new standards for water quality and sustainability.In conclusion, [company name]'s UF water treatment equipment is a game-changer in the water treatment industry. With its cutting-edge technology, environmental sustainability, and commitment to customer satisfaction, the company is setting new benchmarks for clean water solutions. As the world continues to grapple with water scarcity and contamination, [company name] is leading the way in providing reliable and effective UF water treatment solutions that have the potential to transform countless lives and communities around the world.

Revolutionary Screw Press: Discover the Ultimate Solution for Enhanced Efficiency

[News Content]Title: Cutting-Edge Industrial Screw Press Revolutionizes Manufacturing ProcessesIntroduction:The industrial sector is experiencing a remarkable transformation with the introduction of advanced machinery and equipment. In this context, the Screw Press, a groundbreaking technology pioneered by a leading manufacturing company, is revolutionizing manufacturing processes across industries. Committed to delivering cutting-edge solutions, the company has developed an industrial Screw Press system that offers unprecedented efficiency, cost-effectiveness, and environmental sustainability. This latest innovation is poised to reshape the manufacturing landscape, providing companies with a competitive edge and contributing to greener industrial practices.Section 1: Unparalleled EfficiencyThe newly developed industrial Screw Press represents a significant milestone in modern manufacturing techniques, offering unparalleled efficiency. Equipped with state-of-the-art design and engineering, this technology optimizes the production process, resulting in higher output rates with minimal downtime. The Screw Press is designed to reduce waste and improve overall productivity by maximizing the extraction and separation of materials. With its innovative mechanisms, it ensures optimal use of resources while maintaining exceptional product quality.Section 2: Cost-Effectiveness and VersatilityCompanies across various sectors are constantly seeking ways to streamline their operations and achieve cost-effectiveness. The industrial Screw Press presents a cost-efficient solution that addresses this crucial need. With its ability to extract and process materials efficiently, this technology lowers production costs significantly. Additionally, this equipment's versatility allows it to handle a wide range of materials, making it adaptable to diverse industrial applications. From food processing to textile manufacturing, the Screw Press promises to reinvent production processes while reducing expenses.Section 3: Environmental SustainabilityIn an age characterized by increasing concern about environmental sustainability, the industrial Screw Press stands as a testament to responsible manufacturing practices. Its efficient design minimizes energy consumption and waste generation, ensuring a reduced carbon footprint. By effectively extracting and separating materials, this technology enables efficient waste disposal or potential recycling, making it an eco-friendly choice for companies worldwide. The Screw Press not only reduces environmental impact but also aligns businesses with evolving regulations and sustainability goals.Section 4: Safety and ReliabilitySafety and reliability are top priorities in any industrial setting. The company behind the Screw Press has meticulously engineered this technology to prioritize worker safety and operational reliability. Integrated safety features and rigorous testing ensure operators can carry out their tasks without unnecessary risks, safeguarding both machinery and personnel. Its robust design also guarantees long-term durability, minimizing costly downtimes and maintenance expenses.Section 5: Advancements in Smart TechnologyAs technological advancements continue to shape the industrial landscape, the Screw Press is at the forefront of integrating smart technology into manufacturing processes. With advanced automation capabilities, this equipment monitors and adjusts various parameters in real-time, ensuring optimal performance and minimizing human error. By harnessing the power of data analytics and machine learning algorithms, the Screw Press maximizes productivity while streamlining the manufacturing workflow.Conclusion:The industrial Screw Press, developed by an innovative manufacturing company spearheading technological advancements, is revolutionizing manufacturing processes. Through its unparalleled efficiency, cost-effectiveness, and commitment to environmental sustainability, this groundbreaking technology is reshaping the manufacturing landscape globally. With an emphasis on safety, reliability, and integration with smart technology, the Screw Press is paving the way for a more efficient, eco-conscious, and competitive future in industrial manufacturing.

Benefits of Using Glass Reinforced Plastic Piping in Various Industries

Glass Reinforced Plastic Piping – A Robust Solution for Diverse IndustriesGlass Reinforced Plastic Piping, commonly called GRP Piping, is a modern solution that offers a range of benefits to different industrial sectors. It is used in various applications, including chemical processing, waste management, oil and gas, desalination plants, and water treatment facilities. Its usefulness in these industries has made it a reliable and essential product for optimizing operational efficiency and reducing overall costs.A Brief Introduction to the CompanyOne of the leading manufacturers of GRP Piping is a well-known Gujarat-based company. Established over three decades ago, the company has achieved significant milestones in the composites, wind energy, and infrastructure sectors. Their manufacturing unit is equipped with advanced technology that enables them to produce high-quality GRP pipes, fittings, and tanks. Their product range is designed to cater to customers' needs in industries ranging from infrastructure and construction to oil and gas, water treatment, and chemical processing. Their GRP pipes are marketed under the brand name {removed to comply with the prompt}. Their pipes exceed the international standards of quality, strength, and durability and come in a variety of sizes, classes, and pressure ratings. The company follows international quality standards such as ASTM, AWWA, and ISO to ensure its products comply with the highest industry standards.Manufacturing ProcessThe manufacturing process of GRP pipes is simple yet highly advanced. The pipes are constructed by combining an inner liner, a structural layer, and an outer layer. The inner liner is made of resin that is corrosion-resistant and has a shiny surface. The structural layer, also known as the reinforcement layer, consists of glass fibers. Glass fibers are made from basalt rock or silica sand and woven together to form a fabric. The outer layer or the protective layer is made of resin and gives a smooth finish to the pipes, protecting them from external forces.Advantages of GRP PipingThere are several benefits of GRP Piping that have made it the preferred choice of industries worldwide. Firstly, it is corrosion-resistant because of its chemically inert composition. As a result, it can withstand harsh chemicals and corrosive substances that are used in the chemical processing industries. Secondly, it has high strength-to-weight ratio and can withstand high-pressure applications while being lightweight and easy to handle. Thirdly, it has a long lifespan, which makes it a cost-effective and sustainable solution. It requires minimal to no maintenance, reducing the overall cost of the product's lifecycle. Fourthly, it is hygienic and safe for drinking water applications as it does not react with the water and does not contribute to bacterial growth.Applications of GRP PipingGRP Piping has various applications across different industries. One of its essential uses is in water treatment facilities, where it is used for transporting drinking water. Its hygienic properties make it the preferred choice for this application. It is also used in desalination plants for transporting seawater. Its resistance to corrosion and high strength-to-weight ratio make it an excellent choice for this application.In chemical processing industries, GRP Piping is used for transporting highly concentrated acids and other chemicals. It is suitable for this application because of its corrosion-resistant properties. In oil and gas industries, it is used for transporting crude oil and natural gas. Its corrosion-resistant properties and high strength-to-weight ratio make it an excellent choice for this application.ConclusionThe manufacturing of GRP Piping has revolutionized the industry by offering reliable and cost-effective solutions for various applications. Its corrosion-resistant properties, high strength-to-weight ratio, and durability make it an excellent choice for industries ranging from water treatment facilities and chemical processing to oil and gas. The Gujarat-based company has emerged as a leader in the manufacturing of GRP Piping and has set new standards in the industry. The company's focus on quality, innovation, and customer satisfaction has allowed it to gain a significant share in the market. As the demand for this product continues to grow, GRP Piping is poised to be the go-to solution for industries worldwide.

Discover the Benefits of Brine Tanks for Your Needs

Title: Innovative Brine Tanks Revolutionize Saltwater Desalination ProcessIntroduction:In today's era of escalating global water scarcity, companies like (need to remove brand name) are at the forefront, actively developing groundbreaking solutions to tackle the world's water crisis. Their latest innovation involves the creation of cutting-edge brine tanks, which have the potential to revolutionize the saltwater desalination process. Through advanced technology and engineering, these tanks address significant challenges faced in traditional desalination methods by improving efficiency and minimizing environmental impact.Body:1. Growing Global Water Challenges and the Need for Sustainable Solutions (100 words) With the demand for freshwater surpassing the available supply in many regions worldwide, the importance of effective and sustainable desalination processes has increased substantially. This holds particularly true for coastal areas, where abundant saltwater resources remain largely untapped. Introducing a novel approach to brine tanks, (brand name) aims to transform the desalination landscape while addressing environmental concerns.2. Advanced Technology Enhancing Efficiency (150 words) Traditional desalination processes often involve high energy consumption and inefficient utilization of resources. However, (brand name)'s brine tanks implement state-of-the-art technology that significantly enhances efficiency. Their tanks utilize advanced membranes engineered to effectively separate freshwater from the brine solution, minimizing power requirements and reducing operating costs. By maximizing yield while minimizing energy consumption, these tanks have the potential to make desalination more economically viable on a larger scale.3. Environmentally Conscious Design (150 words) Environmental sustainability is at the heart of (brand name)'s vision, and their innovative brine tanks reflect this commitment. By utilizing renewable energy sources in the desalination process, such as solar or wind power, the company aims to reduce dependence on fossil fuels and minimize carbon emissions. Additionally, the tanks incorporate recycling systems to recover and reuse valuable resources from the brine solution, further reducing waste and promoting a circular economy. With these environmentally conscious design features, (brand name)'s brine tanks offer a greener alternative to traditional desalination methods.4. Enhanced Durability and Scalability (100 words) (Brand name)'s brine tanks are built to last, with durable materials and robust engineering. The tanks are designed to withstand harsh environments and demanding operational conditions, ensuring long-term reliability and functionality. Furthermore, the company has prioritized scalability, enabling multiple tanks to be seamlessly integrated into large-scale desalination facilities. This flexibility allows for effective adaptation to varying water demands, ensuring a sustainable and resilient solution for communities facing water scarcity.5. Potential for Global Application (150 words) The versatility and effectiveness of (brand name)'s brine tanks make them suitable for implementation in diverse coastal regions worldwide. As freshwater scarcity continues to be a pressing issue, these tanks offer a viable solution for communities and industries heavily reliant on desalination. By providing access to potable water resources, these tanks have the potential to transform livelihoods and foster economic growth in areas struggling with water scarcity. Furthermore, (brand name) aims to collaborate with governments, organizations, and local communities to customize the implementation of their technology, ensuring maximum benefit and positive impact for all stakeholders involved.Conclusion (50 words) (Brand name)'s brine tanks represent a remarkable contribution to the field of desalination technology. By combining advanced engineering, sustainable design, and scalability, these innovative tanks offer an efficient, environmentally conscious, and economically viable solution to global water scarcity. Their potential impact on the lives of millions cannot be overstated.(Note: The actual brand name was mentioned in the instructions to be removed from the content above.)

Exploring the Benefits and Applications of FRP Pipe: Everything You Need to Know

FRP pipes are a crucial component of various industries, including water treatment, chemical processing, and oil and gas production. These pipes are made from fiberglass reinforced plastic, which provides them with a range of benefits over traditional pipes made from materials such as steel or PVC. Now, one leading company in the industry is offering a wide range of FRP pipes that are designed to provide superior strength, durability, and longevity.This innovative company is dedicated to designing and manufacturing high-quality FRP pipes for use in a diverse range of applications. They offer a variety of pipe solutions for various industries, including wastewater treatment, desalination plants, mining operations, and more. Their pipes are engineered to withstand harsh environments and severe weather conditions, making them an excellent choice for organizations that require reliable, long-lasting piping systems.The company's FRP pipes are constructed using a unique process that involves wrapping fiberglass strands around a central core or mandrel. The fiberglass is then impregnated with resin to create a composite material that is lightweight yet incredibly strong. The result is a pipe that can withstand high pressures, extreme temperatures, and corrosive chemicals, making it ideal for use in a wide range of applications.One of the key benefits of FRP pipes is their resistance to corrosion. Unlike traditional steel pipes, which are susceptible to rust and corrosion over time, FRP pipes are highly resistant to the effects of chemical corrosion. This makes them ideal for use in wastewater treatment plants, chemical processing facilities, and other environments where corrosive substances are present.In addition to their superior corrosion resistance, FRP pipes are also lightweight and easy to install. This makes them an excellent choice for organizations that need to install piping systems quickly and efficiently. Unlike traditional steel pipes, which can be heavy and difficult to maneuver, FRP pipes are lightweight and easy to transport, making them an excellent option for remote locations or sites with difficult access.The company offers a wide range of FRP pipes in varying sizes, configurations, and materials. This allows organizations to choose the best pipe solution for their specific application. Whether they need a standard FRP pipe or a custom solution, the company can provide them with a reliable and high-quality product that will meet their needs and exceed their expectations.In addition to their innovative pipe solutions, the company also provides exceptional customer service and technical support. Their team of experts is available to answer questions, provide guidance, and help organizations choose the best piping solution for their unique needs. They are committed to providing their customers with the highest level of support and service, ensuring that they have a reliable and sustainable piping solution for years to come.Overall, the company's FRP pipes offer a range of benefits over traditional piping materials, making them an excellent choice for organizations in a variety of industries. With their superior strength, durability, and corrosion resistance, these pipes offer a long-lasting and sustainable solution that can withstand the most challenging environments and applications. Whether they need a standard product or a customized solution, organizations can trust this leading company to provide them with the highest-quality FRP pipes available today.

The Essential Components of Cooling Towers: A Comprehensive Guide

Cooling Tower Components (need remove brand name) has recently announced that they will be introducing a new line of cutting-edge cooling tower components to their already impressive range of products. The company, known for their expertise in the field of industrial cooling solutions, has been a leading player in the market for many years and their commitment to innovation and quality has solidified their reputation as a trusted partner for a wide range of industries.The new line of cooling tower components is set to include state-of-the-art materials and designs that will improve the efficiency and performance of cooling towers across the board. With a focus on durability and sustainability, the components are designed to withstand the rigors of industrial use while contributing to more eco-friendly cooling solutions."We are thrilled to be introducing this new line of cooling tower components," said a spokesperson for the company. "Our team has worked tirelessly to develop these products, and we believe that they will set a new standard for excellence in the industry. We are confident that our customers will see the benefits of these components in terms of improved performance, longevity, and overall cost-effectiveness."In addition to the new line of components, Cooling Tower Components (need remove brand name) has also invested in expanding their manufacturing capabilities to meet the growing demand for their products. By increasing their production capacity, the company aims to better serve their customers and ensure that they are able to deliver on their promise of high-quality, reliable cooling solutions.The company's commitment to innovation and customer satisfaction is further reflected in their dedication to ongoing research and development. Their team of experts continually seeks out new technologies and materials to improve their products, ensuring that they remain at the forefront of the industry.One of the key reasons for Cooling Tower Components' (need remove brand name) success is their ability to provide customized solutions that meet the specific needs of each client. Whether it's a large-scale industrial cooling project or a smaller, specialized application, the company has the expertise and resources to deliver tailored solutions that meet and exceed expectations.The company's dedication to excellence is also evident in their rigorous quality control processes. Each component undergoes thorough testing to ensure that it meets the highest standards for performance and durability. This commitment to quality gives their customers peace of mind, knowing that they can rely on Cooling Tower Components (need remove brand name) for consistently reliable products.As a company with a global reach, Cooling Tower Components (need remove brand name) has built a strong network of partners and distributors around the world. This allows them to efficiently serve clients in a wide range of industries and locations, offering them access to industry-leading cooling solutions regardless of their specific needs or geographical location.With the introduction of their new line of cooling tower components and their ongoing commitment to excellence and innovation, Cooling Tower Components (need remove brand name) is well-positioned to continue their leadership in the industrial cooling solutions market. Their dedication to quality, customer satisfaction, and environmental responsibility make them a trusted partner for businesses around the world, and their new products are sure to further solidify their position as an industry leader.

Durable and Lightweight Vessel for Various Applications

A leading composite materials manufacturer, known for its cutting-edge technology and innovative products, has recently introduced a new FRP vessel into the market. The company, with a strong focus on research and development, has gained a reputation for delivering high-quality, durable, and reliable composite materials for various industries.The newly launched FRP vessel is designed to meet the growing demand for advanced materials in the field of chemical processing, water treatment, and industrial storage. With its superior strength, corrosion resistance, and lightweight design, the vessel offers a wide range of benefits for industrial applications.Made from high-quality fiberglass reinforced polymer (FRP), the vessel is capable of withstanding harsh environmental conditions and chemical exposure, making it an ideal choice for industries that require durable and long-lasting storage solutions. Its corrosion-resistant properties make it suitable for storing a variety of chemicals, acids, and corrosive substances without the risk of degradation or contamination.The company's expertise in composite materials and advanced manufacturing techniques has allowed them to create a vessel that not only meets industry standards but also exceeds performance expectations. With a focus on quality and reliability, the company has ensured that the FRP vessel undergoes rigorous testing and quality control measures to guarantee its durability and safety in demanding industrial environments.In addition to its superior performance, the FRP vessel is also designed with ease of installation and maintenance in mind. Its lightweight nature makes it easier to transport and maneuver, reducing installation time and costs. Furthermore, its non-corrosive properties eliminate the need for frequent maintenance and inspection, resulting in long-term cost savings for industrial operators.The company's commitment to sustainability is also reflected in the design of the FRP vessel, which is 100% recyclable and environmentally friendly. By choosing a composite material over traditional metal alternatives, industries can significantly reduce their carbon footprint and contribute to a more sustainable future.With its extensive experience in the field of composite materials, the company has positioned itself as a trusted partner for industries seeking advanced solutions for their storage and processing needs. From design and manufacturing to installation and support, the company offers comprehensive services to ensure that the FRP vessel meets the specific requirements of each customer.By introducing the new FRP vessel, the company aims to further strengthen its position as a leader in the composite materials industry while providing industries with cutting-edge solutions to enhance their operations. With a strong focus on innovation and customer satisfaction, the company is poised to make a significant impact on the industrial storage and processing market with its latest offering.As industries continue to seek sustainable and reliable solutions for their storage and processing needs, the demand for advanced composite materials such as the FRP vessel is expected to rise. With its unmatched strength, durability, and corrosion resistance, the vessel offers a compelling solution for industries looking to enhance their infrastructure and operations.The launch of the new FRP vessel reaffirms the company's commitment to delivering innovative and sustainable solutions that meet the evolving needs of industries. With its proven track record of excellence, the company is well-positioned to drive further growth and success in the composite materials market while helping industries achieve their operational goals.

Efficient and Cost-Effective Sludge Dewatering System for Industrial Applications

Sludge Dewatering System revolutionizing wastewater treatment industryInnovative and efficient sludge dewatering system is making waves in the wastewater treatment industry, offering a cost-effective and sustainable solution for the management of sludge generated during the treatment process. The system, designed and manufactured by a leading environmental technology company, is garnering attention for its ability to significantly reduce the volume of sludge while producing high-quality, reusable water.The sludge dewatering system operates through a series of advanced processes that efficiently separate solids from liquids, resulting in a substantial reduction in the volume of sludge. This not only minimizes the environmental impact of sludge disposal but also offers significant cost savings for wastewater treatment plants, as the volume of sludge that needs to be transported and disposed of is greatly diminished.Additionally, the system is equipped with state-of-the-art technology that ensures the highest quality of treated water, which can be reused or safely discharged into the environment. This not only aligns with stringent environmental regulations but also supports sustainable water management practices.The company behind the innovative sludge dewatering system has a long-standing reputation for developing cutting-edge environmental technologies aimed at addressing the challenges of wastewater treatment and management. With a strong focus on research and development, the company has consistently pushed the boundaries of innovation in the industry, leading to the development of advanced solutions that are making a real difference in the way wastewater is treated and managed.Moreover, the company takes pride in its commitment to sustainability, ensuring that its technologies not only deliver superior performance but also contribute to the overall environmental objectives of its clients. This dedication to sustainability is reflected in the design and functionality of the sludge dewatering system, which not only reduces the environmental impact of sludge disposal but also enables the reuse of treated water, further conserving this precious resource.In addition to its technological advancements, the company also sets itself apart through its comprehensive support and service offerings. This includes expert guidance on system selection, installation, and ongoing maintenance, ensuring that clients can fully optimize the performance and longevity of their sludge dewatering system. This level of support has earned the company a reputation for delivering exceptional customer satisfaction, further solidifying its position as a leader in the environmental technology industry.The impact of the sludge dewatering system is being felt across the wastewater treatment sector, with numerous facilities adopting the technology to enhance their operations. From municipal treatment plants to industrial facilities, the system is proving to be a game-changer, offering a reliable and efficient solution for the management of sludge that was previously considered a costly and challenging aspect of the treatment process.Looking ahead, the company is committed to further advancing its technologies to meet the evolving needs of the wastewater treatment industry. With a focus on continuous innovation and sustainability, the company is poised to remain at the forefront of environmental technology, driving positive change in the way wastewater is managed and treated.In conclusion, the sludge dewatering system developed by the leading environmental technology company is setting a new standard for efficiency and sustainability in the wastewater treatment industry. With its advanced processes, high-quality treated water, and commitment to customer support, the system is proving to be a valuable asset for facilities seeking to improve their sludge management practices. As the company continues to innovate and expand its offerings, it is clear that the impact of the sludge dewatering system will be felt for years to come, driving positive change in the industry and beyond.

Fiberglass Pressure Fittings: Enhancing Efficiency and Durability in Industrial Applications

Fiberglass Pressure Fittings: Durable and Versatile Solution for Industrial ApplicationsFiberglass pressure fittings are gaining popularity in various industrial applications due to their durability, versatility, and resistance to corrosion and chemicals. These fittings have been widely used in the oil and gas industry, chemical processing plants, wastewater treatment facilities, and other harsh environments where traditional metal fittings can easily corrode and fail. In this article, we will discuss the benefits and features of fiberglass pressure fittings, as well as their best applications.Overview of Fiberglass Pressure FittingsFiberglass pressure fittings are made of reinforced plastic composite materials that are composed of polyester resin, glass fibers, and other additives that improve their mechanical properties. The manufacturing process involves the use of specialized molding equipment that produces complex shapes and sizes of fittings that can withstand high-pressure and temperature environments.One of the key features of fiberglass pressure fittings is their resistance to corrosion and chemicals. These fittings are not affected by most acids, alkalis, bleaches, and solvents, making them ideal for corrosive environments. They are also resistant to UV radiation, which is essential for outdoor applications where exposure to sunlight can cause degradation of materials.Another advantage of fiberglass pressure fittings is their high strength-to-weight ratio. Fiberglass is a lightweight material that is up to five times stronger than steel, making it an excellent choice for applications where weight is a concern. The high strength-to-weight ratio also makes fiberglass pressure fittings easier to install and handle than metal fittings, reducing labor costs and downtime.Benefits of Fiberglass Pressure Fittings1. Durability: Fiberglass pressure fittings are highly durable and can last for decades in harsh environments without experiencing any corrosion or degradation. They are also resistant to cracking and chipping, which can be a common problem with metal fittings.2. Low Maintenance: Fiberglass pressure fittings require little maintenance over their lifespan due to their high durability and resistance to corrosion. They do not need to be painted or coated, which reduces maintenance costs and downtime.3. Versatility: Fiberglass pressure fittings can be manufactured in various shapes and sizes, making them versatile for different applications. They can also be customized to meet specific design requirements, allowing for greater flexibility in installation.4. Cost-effective: While fiberglass pressure fittings may cost more upfront than some metal fittings, they offer a cost-effective solution in the long run. Their durability and low maintenance requirements reduce replacement and repair costs, making them a financially wise investment.Best Applications of Fiberglass Pressure Fittings1. Oil and Gas Industry: Fiberglass pressure fittings are commonly used in the oil and gas industry for their resistance to corrosion and chemicals. They are often used in pipelines, tanks, and other equipment where exposure to harsh chemicals and conditions is common.2. Chemical Processing Plants: Fiberglass pressure fittings are also ideal for chemical processing plants, where exposure to corrosive and hazardous chemicals is prevalent. They are used in various applications, including pumping stations, mixing tanks, and storage facilities.3. Wastewater Treatment Facilities: Fiberglass pressure fittings are often used in wastewater treatment facilities due to their resistance to corrosion and moisture. They are used in applications such as pumping stations, process tanks, and piping systems.4. Marine Applications: Fiberglass pressure fittings are also suitable for marine applications due to their resistance to corrosion from saltwater. They are used in various marine applications such as piping systems, holding tanks, and water treatment facilities.Brand Introduction{The brand name has been removed} is a leading manufacturer and supplier of fiberglass pressure fittings in the United States. The company specializes in the production of high-quality composite materials that meet the demands of various industrial applications. With over eight decades of experience, {the brand name} has established itself as a trusted name in the fiberglass industry.{The brand name} offers a range of fiberglass pressure fittings that are designed to meet specific requirements and applications. They can manufacture fittings in various shapes and sizes, including tees, elbows, reducers, and couplings. The company also provides custom fabrication services to meet unique design specifications.ConclusionFiberglass pressure fittings are an ideal choice for industrial applications where corrosive and harsh environments are prevalent. They offer durability, versatility, and cost-effectiveness that make them a preferred choice over traditional metal fittings. With {the brand name}'s high-quality fiberglass pressure fittings, industries can benefit from superior performance, reduced maintenance costs, and increased uptime.